Welcome high speed sorting to tough place.

High-speed sorting is a significant Step for companies to help the speed up the process of organizing items and choosing their categories. But this can struggle to accomplish high-speed sorting reliably in the harshest environments. In addition to the fact that this kind of environment does poor things to people,it is also terrible for high-speed sorting operations; the presence of dust, heat and ice can wreak havoc with a variety of equipment used in automated sortation, which may lead to wastage and damages or losses of the items being processed.

How to Keep Sorting Stable Even in Extreme Conditions

Reliable sorting operations even in extreme conditions can be guaranteed with the help of multiple possible strategies: Using extremely durable, professional sorting equipment which can combat rough weather conditions is one way to go about it. Specialized equipment designed to withstand the conditions of these types of environments will have better seals against dust and moisture, and handle temperature fluctuations more reliably.

Another method is by keeping the sorting equipment regularly clean and proper maintenance to avoid build-up of dust or debris which could impact its functioning. With proper maintenance, doctors can expect the equipment to last longer and continue to function properly in tough environments.

How To Have High-Speed Sorting In Difficult Environments

High-speed sorting in harsh environments are achieved with rights equipment, maintenance, and operations. The best method to execute high-speed sorting is with an extreme duty-specific sorting technology. Such a technology can obviously cater to higher speeds and accuracy in sorting even in the toughest of environment.

Operator should also be well trained on how to run all the sorting equipment and how to keep best running in extreme sorts. The right processes and new technology can help companies to sort quickly in tough environments.

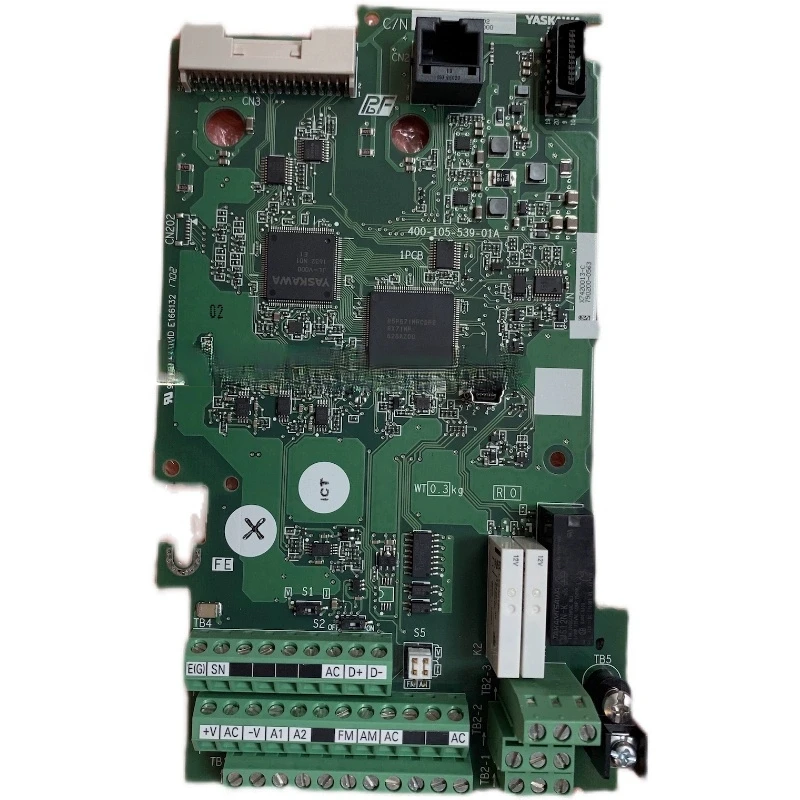

Photos: An Electronic Components Inside Look at Maintaining Reliable Sorting in Harsh Conditions

Planet: Companies that depend on high-speed sorting operations must have a reliable solution in harsh sorting conditions. While companies can insure for reliability by investing in high-quality sorting equipment, implementing manufacturer-recommended maintenance schedules and training operators to effectively sort through challenging conditions.

These can be addressed by inspecting the sorting equipment Displays, Signage and Optoelectronics at regular intervals to catch any broken parts in their infancy. Solving small problems sooner rather than later can help to avoid downtime and keep all distribution processes working the way that they should.

How do you optimize your fast sorting for demanding environments

High speed sorting performance in challenging environments is about the technology — service & spares quality too, and training. Even among harsh conditions, companies can find ways that offer high speed sorting performance through the installation of sophisticated anti-mixed material technology.

In addition to this, it is essential for companies to implement a preventative maintenance program Electrical Equipment & Supplies that keeps sortation equipment in its best shape. Regular cleaning and checking of equipment could avoid problems with sorting performance from occurring.

So there it is, with the right methods and practices reliable high-speed sorting even in harsh conditions can be achieved. Successful in adverse environments Aiming to deliver the lowest operational cost per ton, companies have invested in the quality of their equipment maintenance regimes and are training operators to ensure very best sorting performance is maintained.