In today’s fast-paced industrial landscape, accuracy, efficiency, and precision form the backbone of successful business operations. Whether you’re launching a new product, managing a construction project, or manufacturing complex machinery, the foundation lies in how well your vision is translated into tangible specifications. This is where custom technical drawings play an irreplaceable role.

Understanding Custom Technical Drawings

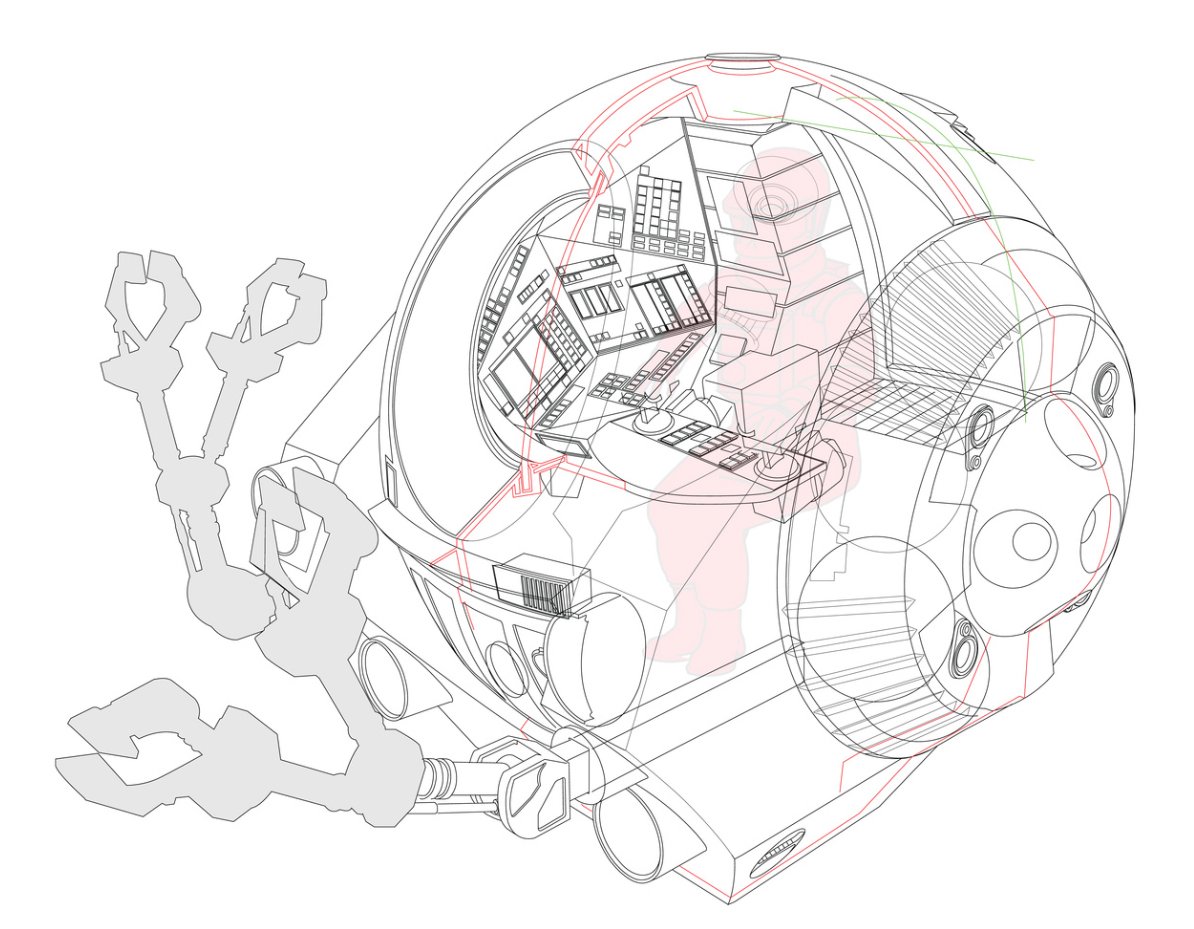

Custom technical drawings are specialized, highly detailed graphical representations of parts, systems, or structures tailored to the specific requirements of a project or client. Unlike generic diagrams or off-the-shelf blueprints, these drawings are designed from scratch or significantly modified to suit unique operational or functional needs.

These drawings go beyond visual depiction—they incorporate exact dimensions, tolerances, materials, surface finishes, assembly instructions, and manufacturing notes. They are used across various industries, including architecture, engineering, manufacturing, aerospace, automotive, and construction.

Key Components of Custom Technical Drawings

To appreciate their importance, it’s crucial to understand what these drawings typically include:

- Precise dimensions and scaling

- Material specifications

- Assembly or disassembly instructions

- Mechanical properties and tolerances

- Annotations and revision history

- Views (top, side, section, isometric)

The inclusion of these elements ensures that every stakeholder—from engineers and machinists to suppliers and clients—is on the same page.

Why Are Custom Technical Drawings Essential for Businesses?

1. Tailored Solutions for Unique Requirements

No two projects are exactly the same. Whether a client needs a part to fit into an existing system or a manufacturer is building a one-of-a-kind prototype, generic blueprints won’t suffice. Custom technical drawings provide a solution that is specifically designed to meet the functional and spatial constraints of a given project, eliminating guesswork and incompatibility.

2. Improved Communication Across Departments and Stakeholders

In a business environment involving multiple departments—engineering, design, production, procurement—communication gaps can result in costly errors. Custom technical drawings act as a universal language, providing clear, visual, and measurable data that all parties can interpret consistently. This leads to more effective collaboration and fewer misunderstandings during the product development cycle.

3. Enhanced Precision and Reduced Errors

Errors in fabrication or construction often stem from poorly documented or misinterpreted specifications. With custom technical drawings, every element of a component or structure is carefully defined, reducing the likelihood of mistakes during production. This not only saves time and materials but also minimizes rework and costly delays.

4. Support for Prototyping and Iterative Design

Businesses focused on innovation often go through multiple iterations before finalizing a product. Custom technical drawings support this process by allowing design teams to make incremental changes with clear documentation. Every revision is traceable, helping teams analyze performance and quality while ensuring consistency from version to version.

5. Compliance and Standardization

In regulated industries like aerospace, healthcare, and construction, adherence to standards and codes is mandatory. Custom technical drawings ensure that designs comply with both international standards (like ISO, ANSI, or DIN) and industry-specific regulations. This protects companies from legal issues, fines, and safety violations.

6. Optimized Manufacturing Processes

Custom technical drawings provide the essential data required by CNC machines, 3D printers, and other automated manufacturing systems. By offering exact dimensions, tolerances, and material details, these drawings help manufacturers produce components with high accuracy and repeatability. This improves efficiency, reduces waste, and supports lean manufacturing practices.

7. Competitive Advantage in B2B Relationships

In a competitive market, businesses that can offer tailored solutions and faster turnaround times often outperform their peers. Custom technical drawings facilitate this by enabling faster design finalization, better quality control, and a more streamlined production process. Companies that can provide this level of customization are more likely to win contracts, especially in industries requiring high precision and customization.

Who Creates Custom Technical Drawings?

Creating custom technical drawings is typically the job of trained professionals such as:

- Mechanical Engineers

- CAD Designers

- Drafters

- Architects

- Product Designers

They use advanced software tools like AutoCAD, SolidWorks, CATIA, Revit, and Fusion 360 to create and revise these drawings. Businesses may choose to develop in-house capabilities or outsource this function to specialized service providers.

Real-World Business Applications

Manufacturing

In precision manufacturing, every millimeter counts. A slight variation in dimensions can lead to malfunction or failure. Custom technical drawings provide machinists and engineers with exact information required for flawless production.

Architecture & Construction

From electrical plans to HVAC layouts and structural blueprints, custom drawings ensure that every detail is documented for regulatory approval and on-site execution. Miscommunication or omission here can lead to major project delays and cost overruns.

Product Development

Companies developing new products rely on technical drawings to communicate design intent, file patents, and secure investments. These drawings are often included in R&D documentation, grant proposals, and product manuals.

Industrial Equipment

OEMs and heavy equipment manufacturers use custom drawings to tailor machines to specific applications, customer environments, or operational requirements. This level of customization often determines the long-term success of the equipment in the field.

Outsourcing vs. In-House Drawing Capabilities

Some businesses opt to build an in-house team of drafters and CAD technicians, especially when frequent updates or confidential projects are involved. Others may choose to outsource custom technical drawing services to reduce costs and access specialized skills.

When outsourcing, it’s essential to partner with firms that understand your industry, offer multi-format deliverables, and comply with international drawing standards.

Future Trends in Technical Drawing

The evolution of custom technical drawings continues with the integration of AI, cloud-based collaboration tools, and augmented reality. Businesses can now manage drawing versions, review 3D models in virtual environments, and collaborate in real-time, even across continents. These innovations are helping companies bring products to market faster and more efficiently than ever before.

Conclusion

Custom technical drawings are far more than illustrations—they are strategic assets that drive clarity, efficiency, and precision throughout a project lifecycle. From concept to completion, these drawings ensure that every detail is accounted for, every standard is met, and every team is aligned. For businesses aiming to scale, compete, and innovate, investing in high-quality custom technical drawings is not just a technical requirement—it’s a competitive necessity.

Related Reads

- Trusted HVAC Services in Martin County, FL — What Homeowners Should Know

- How SEO company in Surat Can Grow Your Organic Reach

- RFI Shielding Materials: Ensuring Complete Electromagnetic Protection

- The Evolution of Digital Ads Through AI Modern Marketing

- A Night to Remember: The Way the Top Restaurants Make New Year’s Eve an Experience