The Gear hobs are important tools for making precise gears for industries such as automobile, aerospace, and heavy tools. The quality of the gears is determined by their durability. That’s the reason why it’s crucial to go for gear hob manufacturers in India. It is vital not only for getting equips, but also for ensuring that operations run seamlessly and products are of high quality over the period. The following are the explanations why it makes a big difference to ask the professionals to assist.

Unmatched Tooling Accuracy:

Expert gear hob makers have years of technical expertise and a deep knowledge of metallurgy, cutting dynamics, and gear profiles. Their hobs are made with extraordinary care, which guarantees tight tolerances and high-quality gear finishes. That amount of precision is quite crucial for organizations that need their gear to work completely fine. Precision tooling cuts down on the requirement for post-processing and lowers the number of rejected gears, which saves time and money.

Tailored Solutions for Complicated Needs:

Every need for cutting gears is different. Standard tools may not always be able to handle the unique needs of a project, particularly when using non-standard gear shapes or exotic materials. Experienced gear hob cutters suppliers can make hobs that are just right for your gear shape, cutting speeds, and material hardness. Experts can provide the best solutions for your equipment and production system, from spur and helical hobs to worm gear hobs and spline cutters.

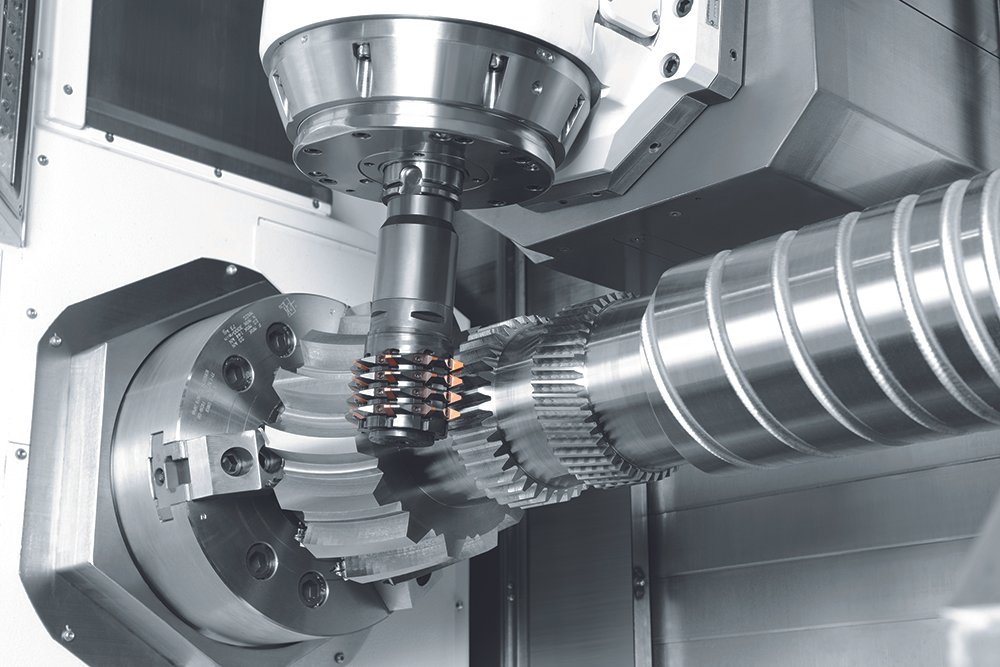

Advanced Manufacturing Facilities:

To make world-class hobs, trusted producers buy high-end CNC machining, multi-axis grinding, and precise measurement tools. Their factories frequently have ISO-certified quality control systems that make sure every tool they send out is the same. New equipment makes it possible to handle both large and small orders quickly and easily, as well as to speed up production and make it more efficient.

Help with Technical Problems and Services After the Sale:

When you hire professionals, you don’t only get a tool; you also get a technical partner. Many of the best manufacturers provide after-sales service that includes fixing tools, keeping track of their performance, and giving advice on how to make them work better. Experts can help to figure out what’s not exactly working with the gear cutting tool, suggest upgraded machining settings, and will explain to you when to regrind or replace a hob as required. Their suggestion will assist you to get the most out of your equipment and avoid unplanned downtime.

Reliability with a Long-Term Relationship:

Manufacturers that have been around for a while know how important it is to produce on time and with consistent quality. Their tried-and-true processes make sure that you always get reliable tools and quick service. Building a connection with these kinds of specialists builds trust and makes it easier to work together for a long time, which is especially helpful for continuing or large-scale manufacturing activities.

Last Thoughts:

In a world where accuracy is key, the quality of your tools has a direct impact on your output. When you choose skilled gear hob manufacturers, you get more than just high-quality hobs. You also get technical know-how, dependable support, and long-term performance advantages. When you need accuracy, long-lasting products, and the capacity to customize, the specialists are the partners you can trust.