Many modern devices use electronic circuit boards as their operational core, which includes mobile phones and laptops and industrial machinery, and everyday electronics. The clean condition of electronic circuit boards determines their operational quality and durability and reliability outcomes. The improper maintenance of circuit boards leads to short circuits and corrosion, and malfunctioning because of dust, dirt, moisture, and residues. This complete tutorial presents step-by-step instructions about electronic circuit board cleaning through multiple cleaning approaches and solutions.

Cleaning Process

The cleaning process of circuit boards remains essential because it affects their operational performance and lifespan, and reliability. Printed circuit boards (PCBs), also known as circuit boards, operate as delicate components needing accurate cleaning methods. The presence of dirt particles and dust together with grime disrupts electrical conductivity and leads to lasting destruction of the circuit board. Regular cleaning helps:

- The cleaning process removes such conductive materials that pose a threat of short circuit formation.

- The performance efficiency improves because cleaning enhances both signal transmission and conductivity.

- The lifespan of components and structures increases because cleaning prevents corrosion and component failure.

- The professional appearance of boards remains intact through regular cleaning efforts.

What Are The Essential Reasons That Make Circuit Board Cleaning Necessary?

Every electronic system containing circuit boards, including industrial equipment, home appliances, and modern devices, develops dust along with grime and residue throughout its operational lifespan. The combination of environmental elements, including humidity, together with smoke and air pollutants, fast-tracks the accumulation of dirt on boards. Cleaning is crucial for:

Electrical pathways experience breakdowns when contaminants enter the system.

Reliability

The reliability of PCBs increases when they remain clean because they operate more effectively and maintain extended service periods. Better signal transmission occurs when resistance decreases through cleaning operations.

Common Contaminants on Circuit Boards

It is crucial to identify the various kinds of contaminants that appear on PCBs before beginning the cleaning operation.

Dust and Debris: Accumulated particles from the environment

The contamination originates from manufacturing and handling activities that produce oils and grease.

Corrosion and Oxidation: Caused by moisture exposure

The residue from soldering operations becomes known as flux residue. Liquid and moisture spills trigger short circuits in addition to causing corrosion damage.

Preparation: Gather the Right Cleaning Supplies

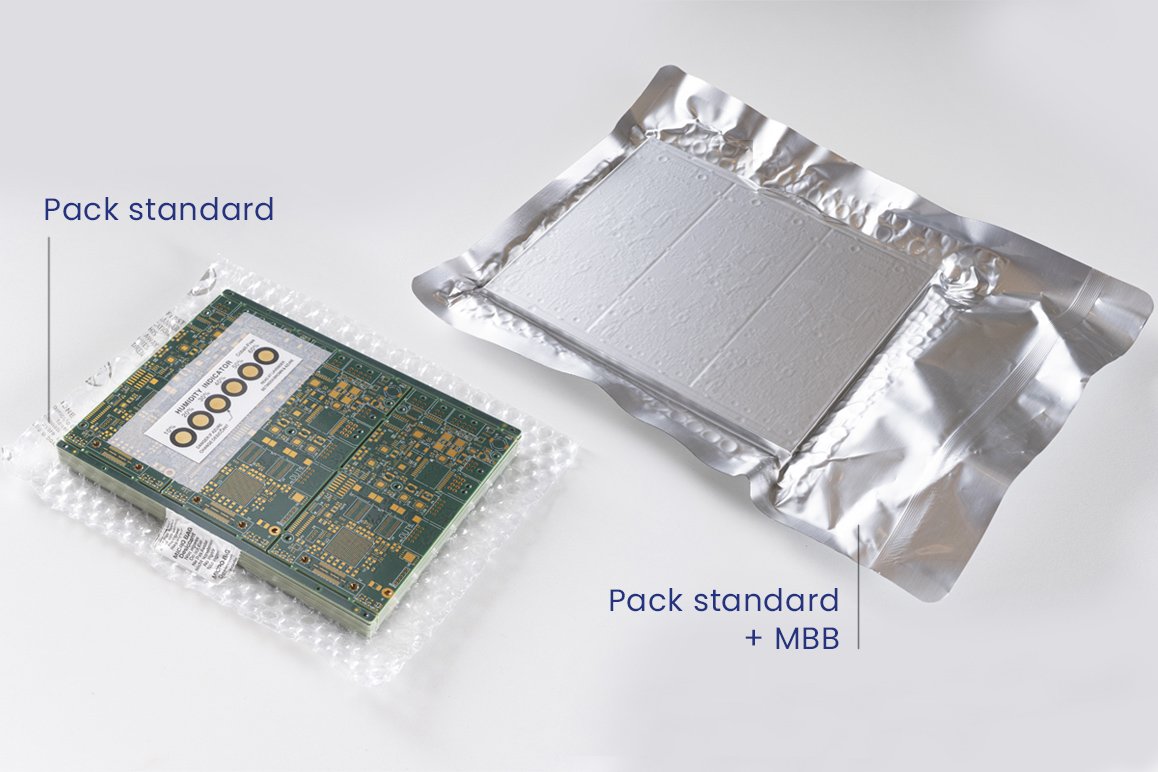

The cleaning process of electronic circuit boards requires these essential materials: circuit board cleaner spray, electronic circuit board cleaner spray, isopropyl alcohol (99%), distilled water, a soft bristle brush, and a compressed air canister. The circuit board cleaner spray, designed for electronic devices, functions as an electronic circuit board cleaner spray. The reliable and safe option to clean PCBs is Isopropyl Alcohol at 99% purity. Proper packaging, such as custom printed mylar bags, can help store and protect sensitive electronic components from dust and moisture.

Use distilled water: It will stop mineral deposits from forming on circuit boards.

A soft bristle brush serves best for removing surface debris from components. A compressed air canister functions to eliminate dust from both PCB surfaces and small spaces. A microfiber cloth, together with a lint-free wipe, protects against static charges and prevents surface damage.

PCB Board Cleaning Solution: Specialized for cleaning PCB boards.

Anti-Static Wrist Strap: Prevents electrostatic discharge.

How to Clean a Circuit Board: Step-by-Step Guide?

Safety Precautions Before Cleaning

Every circuit board handling operation must start with these steps:

- Before beginning, ensure that the device has no connection to any power sources.

- Static discharges require the use of an anti-static wrist strap.

- The cleaning process should utilize only electronic component-specific products.

Cleaning Method 1: Using Isopropyl Alcohol (99%)

Printed circuit boards (PCBs), along with electronic components, benefit most from this cleaning method because of its gentleness.

Materials Needed:

Isopropyl Alcohol (99%), Soft Bristle Brush or Toothbrush, Microfiber Cloth

- The board requires a power cutoff and separation from power sources before cleaning operations.

- You should soak a brush or microfiber cloth with isopropyl alcohol.

- You should clean the board by moving the brush in circular patterns.

- Clean the visible residue first on the affected areas.

- Allow the alcohol to evaporate naturally or blow compressed air across the board to expedite drying time.

- Check the board for residue after drying it completely before turning it on.

Cleaning Method 2: Cleaner Spray

A circuit board cleaner spray serves as the second method to clean electronic components.

Electronic circuit board cleaners serve as specific solutions that perform safe cleaning operations on electronic components.

Materials Needed:

Electronic Circuit Board Cleaner Spray, Compressed Air Canister

- Always disconnect power from the device before proceeding with safety purposes.

- The spray canister must be positioned upright during the even application of the cleaner.

- Let the dissolving process continue for several minutes until the cleaner completes its work.

- Use compressed air to eliminate the excess cleaner along with debris from the board.

- Check the board for complete removal of all contaminants.

Cleaning Method 3: Using Ultrasonic Cleaner

Sound waves from ultrasonic cleaners remove contaminants from PCBs effectively.

Materials Needed:

Ultrasonic Cleaner, PCB Board Cleaning Solution, Distilled Water

- Mix the cleaning solution with distilled water to create a prepared cleaning solution.

- Put the PCB inside the Cleaner until it is completely submerged.

- Set the ultrasonic cleaner timer to operate between 2 and 5 minutes.

- Dry the board with distilled water before allowing it to air dry naturally.

Best Practices for PCB Maintenance

These steps will help you extend the lifespan of your circuit boards:

- Touching PCBs with your bare hands should be avoided since skin oils will trigger corrosion processes.

- The use of Anti-Static Bags protects the boards from static discharge.

- Clean environments should be used to store electronics since they minimize dust accumulation and protect against debris damage.

Regular Cleaning: Clean PCBs every 6-12 months.

The following mistakes must be avoided when cleaning circuit boards:

- Direct application of water leads to both corrosion and short circuits.

- Household cleaning agents should be avoided because they feature strong chemical compounds that harm board components.

- Too much moisture applied to the board will lead to damage.

- Gentle brushing techniques should be used to protect the components from damage.

Conclusion

Electronic circuit boards need regular cleaning to achieve their best operational state as well as extend their lifespan. The correct method of using isopropyl alcohol and circuit board cleaner spray or ultrasonic cleaners will stop malfunctions and increase product lifespan while improving reliability. Custom printed mylar bags offer dust-free protection, which enhances the storage of electronic components. Suitable packaging methods protect PCBs by blocking the entry of contaminants as well as preventing both moisture intrusion and static electricity buildup. Regular maintenance and cleaning of PCB boards keep your electronics operating reliably both for hobbyists and professionals in the technology field.