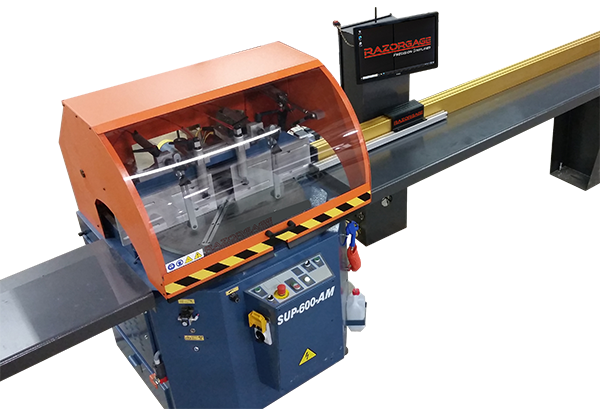

As diligence evolves and demands lesser delicacy in product, inventions in cutting technology are reshaping prospects. Tools like the RazorGage Angle Master are being bandied extensively as implicit game- changers in 2025. The drive toward robotization, digital perfection, and stoner-friendly results has opened a new period for shops and manufactories. With further sectors taking largely accurate cuts, this technology is not only applicable but decreasingly necessary.

Why Precision Cutting Matters More Than Ever

In 2025, perfection is n’t a luxury but a demand across multiple diligence. Whether in construction, essence fabrication, or woodworking, indeed the fewest divagation in cutting angles can beget expensive crimes. High- quality products calculate on cuts that meet exact specifications, which is why perfection slice tools have come central to ultramodern manufacturing processes. The focus is no longer just on speed, but on reducing waste, maximizing effectiveness, and achieving harmonious results.

The Shift from Manual to Automated Systems

Traditional primer cutting styles have served diligence for decades, but robotization is driving a massive metamorphosis. Automated systems allow for quicker setup times, unremarkable delicacy, and reduced reliance on mortal judgment. As professed labor dearths continue to affect diligence, robotization offers a sustainable result by simplifying complex tasks while maintaining thickness. This shift is where angle measuring and cutting technologies are sculpturing their niche in 2025.

The Part of Angle Measurement in Modern Manufacturing

Angle dimension plays a critical part in the slice process. Inaccurate angles can compromise the structural integrity of finished products, lead to wasted accoutrements , and increase costs. In 2025, with the emphasis on spare manufacturing and sustainability, precise angle dimension tools are getting necessary. They ensure that cuts align impeccably with design conditions, minimizing rework and enhancing product effectiveness.

Digital Integration and Smart Capabilities

One of the most notable advancements in 2025 is the integration of digital technology into cutting systems. ultramodern tools give touchscreen interfaces, programmable options, and the capability to store cutting data for unborn use. This digital shift makes the process more intuitive and allows workers of varying skill situations to achieve the same high- quality results. The trend toward smart manufacturing means that cutting technology must acclimatize to seamlessly integrate with broader product systems.

Enhancing Effectiveness with Automated Cutting Processes

effectiveness is a core thing of every product terrain, and 2025 emphasizes doing further with lower. Automated cutting systems reduce time-out by streamlining repetitious tasks. Once programmed, these systems exclude the need for constant adaptations, performing in faster product cycles. Also, harmonious delicacy reduces the quantum of scrap material, making the process more sustainable and cost-effective over time.

Safety Advancements in Precision Cutting

Safety continues to be a top priority in shops and manufactories, and technological advancements are helping address this concern. Automated angle cutting systems minimize the need for workers to handle accoutrements directly during the most dangerous corridor of the process. This reduces the threat of accidents caused by homemade crimes or fatigue. With enhanced safety features and perfection engineering, cutting systems in 2025 are designed to cover drivers while delivering superior performance.

Impact on Diverse Diligence

The influence of perfection angle cutting technology extends across numerous diligence. In woodworking, it ensures that joints fit impeccably and products meet exact design specifications. In essence fabrication, accurate cuts mean lesser strength and continuity in structures. Indeed in lower shops, precise angle slice tools are helping crafters and small manufacturers contend with larger operations by maintaining professional- grade quality. As diligence evolves, the versatility of these systems makes them decreasingly precious.

The Future of Pool and Skill Development

While robotization frequently sparks enterprises about job relegation, in 2025 it’s more accurate to view it as a shift in chops. Drivers no longer need to calculate solely on times of experience to achieve perfection. Rather, they learn to manage digital systems, interpret data, and oversee products with an advanced degree of control. This change makes perfection cutting accessible to a wider pool, while also creating openings for advanced training and technical places.

Conclusion The Path Toward Smarter Cutting Systems

As diligence steps into the future, the demand for delicacy, effectiveness, and safety is stronger than ever. Tools that combine robotization, digital integration, and advanced angle dimension are shaping the coming period of cutting technology. The RazorGage Angle Master represents this shift toward smarter, more precise results that are setting new marks for performance in 2025. As manufacturers continue enriching their processes, the focus will decrease to Optimizing saws in order to meet the challenges of hereafter with confidence and invention.

Related Reads

- Himalayan Royal Transport – Trusted Logistics Company in Birgunj, Nepal for Seamless Cargo Solutions

- How to Find an Austin PR Agency That Gets Your Brand Noticed

- Sofa Set Styling Tips: How to Match Your Sofa with Your Home Decor

- Common Services Offered by a Garage Door Supplier

- What Are Tiny Homes? A Complete Guide to Small Living