Introduction

Every sip of juice, every glass of soda, and every drop of bottled water should taste the same. Consumers expect consistency, and behind that consistency lies filtration. In food and beverage production, even small impurities can change flavor, color, or texture. This is why liquid filtration cartridges play such an important role. This guide explores how these filters improve consistency while protecting product safety. You will also learn why pleated polypropylene filter cartridges are often the top pick for these processes.

Table of Contents

- Why Filtration Is Vital in Food and Beverage Production

- What Are Liquid Filtration Cartridges?

- The Role of Pleated Polypropylene Filter Cartridges

- How Filtration Supports Flavor Consistency

- Safety Benefits of Reliable Filtration

- Efficiency and Cost-Effectiveness in Production

- Key Takeaway

Why Filtration Is Vital in Food and Beverage Production

Food and beverage companies rely on strict quality standards. Even the slightest inconsistency can lead to complaints or product recalls. Filtration helps remove unwanted particles, bacteria, and even micro-sized contaminants. By using the right filter, producers ensure that every batch matches the expected taste, smell, and appearance. For high school students studying science, think of it like a lab experiment: if the same process is repeated correctly, the outcome will always match.

What Are Liquid Filtration Cartridges?

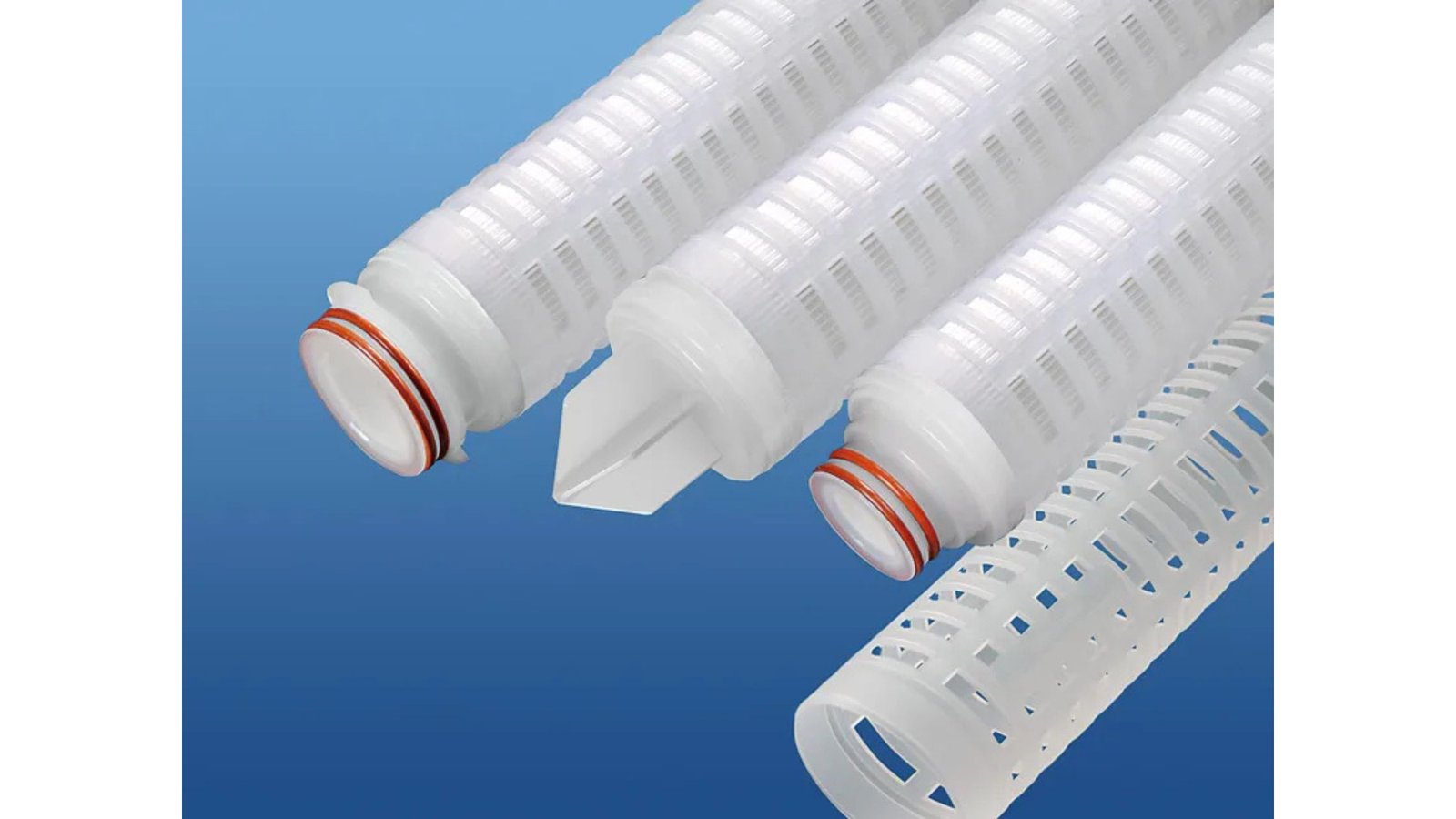

Liquid filtration cartridges are devices designed to clean liquids as they pass through them. They are made from specialized materials that trap solids and other impurities. These cartridges are often shaped like tubes and are easy to install in a filtration system. They can be customized for different levels of particle retention, depending on the product. For example, juice requires finer filtration than water to remove pulp and cloudiness.

The Role of Pleated Polypropylene Filter Cartridges

Among the many cartridge options available, pleated polypropylene filter cartridges are widely used in food and beverage applications. Their pleated design provides a large surface area, which means more particles can be trapped without slowing down liquid flow. Polypropylene material is also resistant to chemicals and is safe for use in consumable products. These qualities make them a trusted choice for consistent and reliable filtration.

How Filtration Supports Flavor Consistency

Taste is one of the most sensitive factors in beverages. Even tiny differences in mineral content or contaminants can alter flavor. For instance, a small amount of sediment in a soda might give it a bitter aftertaste. With liquid filtration cartridges in place, producers can remove these unwanted particles before they affect flavor. Pleated polypropylene filter cartridges are especially effective because their fixed pore structure ensures that the same particles are removed every time. This guarantees that one bottle tastes just like the next.

Safety Benefits of Reliable Filtration

Besides taste, safety is another major concern. Bacteria or other microorganisms can enter beverages during production. If not removed, they can cause health issues for consumers. Reliable filter cartridges for liquids act as barriers, preventing contaminants from entering the final product. This makes them a crucial part of food safety standards. Many countries require such filters in beverage production to meet health regulations.

Efficiency and Cost-Effectiveness in Production

Another advantage of using pleated polypropylene filter cartridges is their efficiency. Because of their pleated design, they last longer and require fewer replacements. This reduces downtime in production and lowers costs over time. A consistent filtration system not only improves product quality but also supports business efficiency. For producers, this means they can meet demand quickly without sacrificing safety or flavor.

Key Takeaway

Liquid filtration cartridges are not just pieces of equipment. They are essential tools that protect flavor, guarantee safety, and keep production efficient. Pleated polypropylene filter cartridges stand out because of their durability, chemical resistance, and ability to provide consistent results across batches. For the food and beverage industry, this level of reliability is what builds consumer trust.

The End Note!

Consistency in food and beverage products depends heavily on reliable filtration. Liquid filtration cartridges help ensure that every drink meets the same high standards, both in taste and safety. Pleated polypropylene filter cartridges, in particular, offer durability and precise performance that make them ideal for producers focused on quality. As a third-party note, Separation Technologies, Inc. provides advanced filtration solutions that support these needs, helping food and beverage companies deliver products that consumers can trust with every sip.