Searching for a manufacturing partner for producing medical devices requires research on the buyer’s part. So to make it easy for you, this guide will show you what to ask and what capabilities a trusted partner should have for your large medical components. Because finding large plastic injection molding companies in China can be difficult if you don’t know where to start looking. You’ll need to know what factors matter most before you sign any contract or begin your project.

What is a Medical-Grade Large Plastic Injection Molding Company?

Precision and Size

Machinery with over a thousand tons of clamping force is used in manufacturing larger plastic parts. These machines can produce large device housings, testing cartridges, and even specialized internal trays. Precision molding means achieving very tight dimensional measurements, sometimes as small as ±0.05 millimeters. This high degree of accuracy is very important for medical devices that need to function perfectly every single time. Similarly, the factory’s technical team must demonstrate success with same sized, high-precision projects.

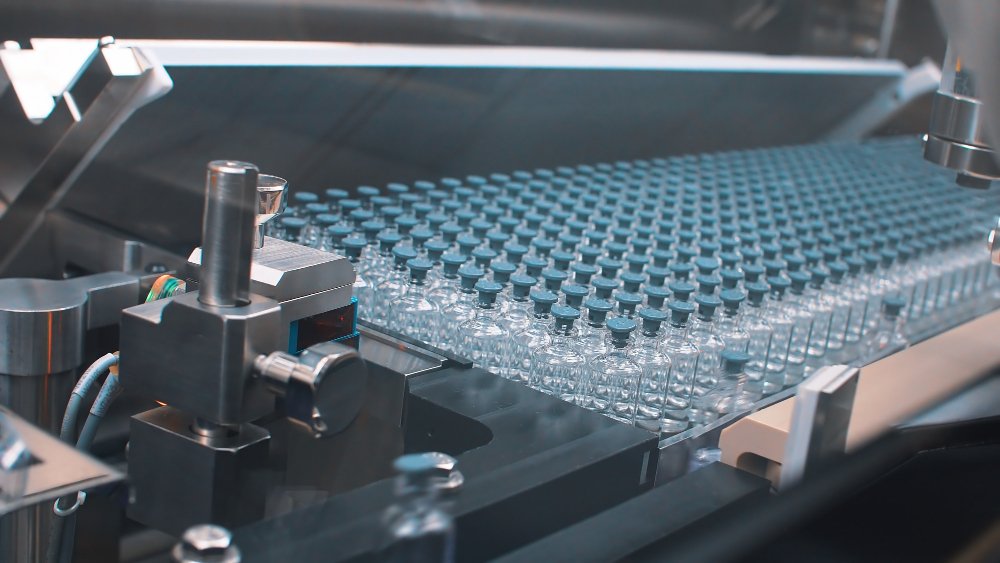

The Importance of Cleanrooms

Medical devices need production in an extremely clean environment to prevent contamination from foreign particles. The most trusted manufacturers operate a controlled cleanroom, often certified as an ISO Class 8 dust-free workshop. This controlled space keeps air quality very high for all manufacturing and assembly processes. So look for companies with a dedicated cleanroom for your component production run. Cleanrooms help manufacturers maintain the necessary sterility and meet the industry’s strict quality benchmarks.

Material Selection Matters

The required plastic material directly affects the safety and performance of the medical product. A trustworthy company will work with specialized plastic resins that are biocompatible and chemically resistant. For example, they commonly use materials like Polycarbonate, Polyethylene, and Polypropylene for these important applications. Make sure the material can handle sterilization processes like high heat or radiation without changing its shape or strength.

Why Consider China for Large Medical Plastic Molding?

Cost-Effectiveness and Scale

One major benefit here is the economical price, especially for creating new tooling and for labor-intensive processes. This can save money on your overall mold and production budget without lowering quality. The sheer scale of the Chinese manufacturing industry provides a competitive pricing advantage. They can also give quite quick turnaround times for both the tooling and the final parts.

Advanced Technology and Expertise

Top Chinese firms have invested heavily in good equipment and advanced automation systems. They now use sophisticated software for mold flow analysis to maximize the design success of the tooling. Their in-house engineers provide expert feedback on your design to improve product durability and lower costs. They have more experience working with different high-performance medical-grade materials, identifying the best resin for your needs.

How to Evaluate Your Molding Partner

Verify Quality Certifications

Always check your potential partner’s quality management certifications before starting a project. The main standard for medical devices is ISO 13485, which confirms a commitment to device safety. You should also look for general quality certifications like ISO 9001 for factory operational standards. The factory must prove they comply with international rules like those set by the FDA or the European Union’s MDR. These certifications show the factory has a trustworthy and controlled manufacturing system.

Demand Design for Manufacturability (DFM)

A good supplier offers a DFM analysis early for every new mold. This DFM review finds design flaws that could cause defects or major problems in production. The manufacturer must check for common issues like uneven wall thickness or sharp internal corners. They should recommend material changes or design fixes to make your part stronger. This early work reduces the risk of expensive changes after the tooling starts.

Inspect Equipment Size and Tonnage

For projects with large parts, you must check the company’s machine size and capacity. Ask about the clamping forces, or tonnage, of their largest injection molding machines. Confirm their machines can handle the physical size and weight of your mold. A capable factory needs a wide range of machinery for different project sizes. They also must have modern inspection tools, like Coordinate Measuring Machines (CMMs), to verify large part accuracy.

Review Quality Control and Traceability

Ask for a detailed look at their Quality Control (QC) process and testing standards. Inquire if they perform CPK tests (Process Capability Index) on production runs to check for consistency. A good company gives material certifications to prove the quality of the plastic resin. They also keep detailed records for traceability, tracking the entire history of the mold and every part produced. This QC system protects the quality and reliability of your finished products.

Demand Clear Communication and Service

Clear and quick communication is very important for a successful partnership. The supplier must offer fluent English communication, ideally with a dedicated project manager for your file. They should give regular updates on production progress and quickly answer your questions. Look for a team that is honest about potential problems discovered during quoting. A professional partner provides a clear mold warranty and spare components. Strong service after production shows a commitment to a long-term partnership.

What to Look for in the Quote

When you receive a quote, look for a detailed breakdown of all costs. This breakdown must separate costs for the mold, the plastic material, and the labor. Be careful of vague or unusually cheap quotes that lack clear details. A good quote specifies the type of steel used for the mold and the expected tool life. They must also give a guarantee on the tool life and agree to the payment terms clearly in the contract.

Key Takeaway

Sourcing a partner for medical-grade parts requires you to focus more on verified quality over the lowest initial price. Thoroughly examining a company’s certifications, equipment capacity, and engineering support can help identify some of China’s reputable large plastic injection molding companies. When you secure a reliable partner, you can start a successful and trustworthy manufacturing relationship. Remember, the right partnership will provide you high-quality, dependable medical components.